SIO-2 Stoneware Ceramic Pottery Clay Assortment, 24 lb - PRAI, PRNI, Berlin, Toffee, Luna, PCLI

$47.95USD

In Stock

- Brand: SIO-2®

- Model #: SIO2-8406AST

Most products ship within 1 business day. Learn More

SIO-2 Stoneware Ceramic Pottery Clay Assortment, 24 lb - PRAI, PRNI, Berlin, Toffee, Luna, PCLI

Unlock your creative potential with this exclusive bundle of six premium stoneware clays! Featuring a diverse range of colors and textures, this set includes PRNI Black for dramatic finishes, Toffee Caramel for warm earth tones, Berlin Grey for bold sculptures, Luna for a speckled surface, PRAI White for crisp, clean forms, and PCLI Paper Clay for lightweight and flexible creations. Ideal for wheel throwing, hand-building, and sculpting, these clays fire to cone 5–10, offering exceptional strength and stunning results. Perfect for artists seeking variety in their work—get yours today!

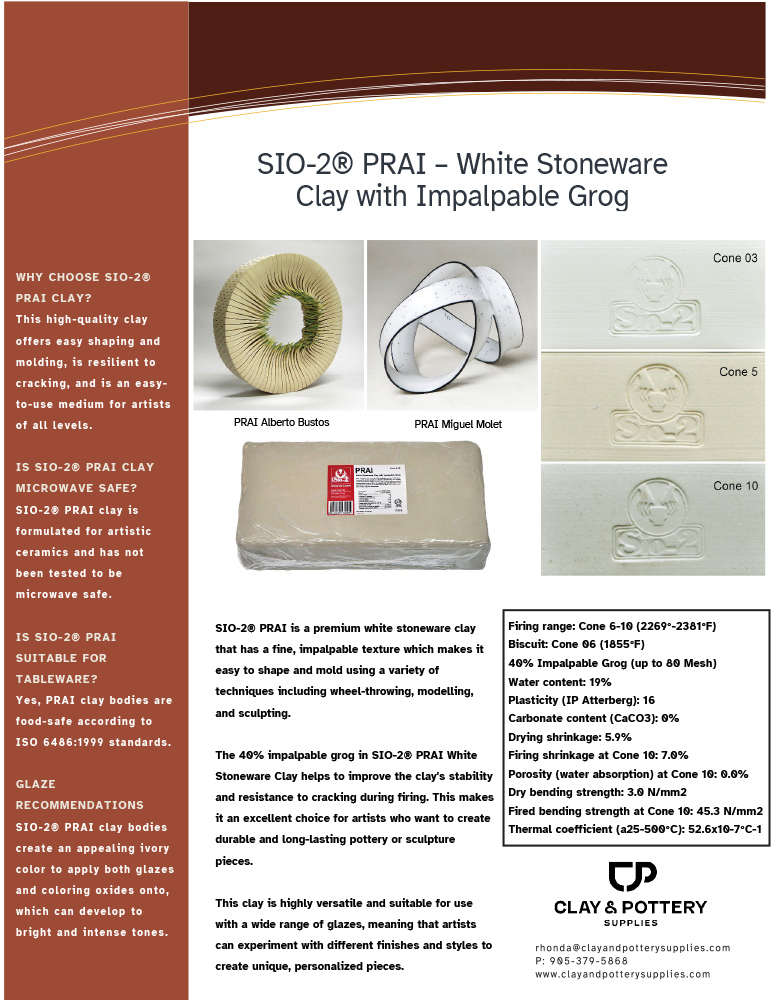

PRAI WHITE

TECHNICAL SPECIFICATIONS:

Firing range: 2269-2369°F / Cone 6-10

Biscuit temperature: 1855°F / Cone 06

Water content: 19%

Plasticity (IP Atterberg): 16

Carbonate content (CaCO3): 0%

Drying shrinkage: 5.9%

Firing shrinkage at Cone 10: 7.0%

Porosity at Cone 10: 0.0%

Dry bending strength: 3.0 N/mm2

Fired bending strength at Cone 10: 51.0 N/mm2

Thermal coefficient (α25-500°C): 60.4x10-7°C-1

Firing range: 1240-1300ºC / Cone 6-10

Biscuit temperature: 1000ºC / Cone 06

Water content: 19%

Plasticity (IP Atterberg): 16

Carbonate content (CaCO3): 0%

Drying shrinkage: 5.9%

Firing shrinkage 1300ºC: 7.0%

Porosity (water absorption) at 1300ºC: 0.0%

Dry bending strength: 3.0 N/mm2

Fired bending strength 1300ºC: 51.0 N/mm2

Thermal coefficient 1250ºC (25-500ºC): 60.4x10^-7ºC^-1

PRNI BLACK

TECHNICAL SPECIFICATIONS:

Firing range: 2205-2269°F / Cone 5-6

Biscuit temperature: 1855°F / Cone 06

Water content: 21%

Plasticity (IP Atterberg): 19

Carbonate content (CaCO3): 0%

Drying shrinkage: 8.2%

Firing shrinkage at Cone 6: 5.4%

Porosity at Cone 6: 4.0%

Dry bending strength: 5.9 N/mm2

Fired bending strength at Cone 6: 51.4 N/mm2

Thermal coefficient (α25-500°C): 63.8x10-7°C-1

Firing range: 1200-1240ºC / Cone 5-6

Biscuit temperature: 1000ºC / Cone 06

Water content: 21%

Plasticity (IP Atterberg): 19

Carbonate content (CaCO3): 0%

Drying shrinkage: 8.2%

Firing shrinkage 1240ºC: 5.4%

Porosity (water absorption) 1240ºC: 4.0%

Dry bending strength: 5.9 N/mm2

Fired bending strength 1240ºC: 51.4 N/mm2

Thermal coefficient 1240ºC (25-500ºC): 63.8x10^-7ºC^-1

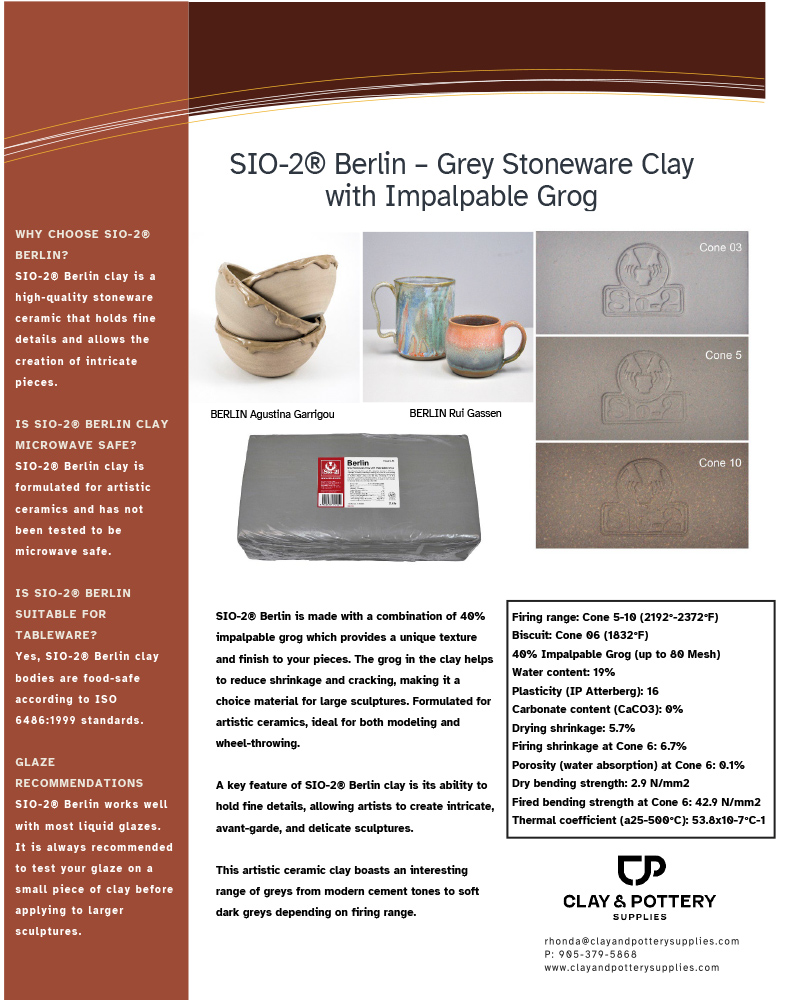

BERLIN GRAY

TECHNICAL SPECIFICATIONS:

Firing range: 2269-2381°F / Cone 5-10

Biscuit temperature: 1855°F / Cone 06

Water content: 19%

Plasticity (IP Atterberg): 16

Carbonate content (CaCO3): 0%

Drying shrinkage: 5.7%

Firing shrinkage at Cone 10: 6.4%

Porosity at Cone 10: 0.1%

Dry bending strength: 2.9 N/mm2

Fired bending strength at Cone 10: 53.2 N/mm2

Thermal coefficient (α25-500°C): 60.1x10-7°C-1

Firing range: 1200-1300ºC / Cone 5-10

Biscuit temperature: 1000ºC / Cone 06

Water content: 19%

Plasticity (IP Atterberg): 16

Carbonate content (CaCO3): 0%

Drying shrinkage: 5.7%

Firing shrinkage 1300ºC: 6.4%

Porosity (water absorption) at 1300ºC: 0.1%

Dry bending strength: 2.9 N/mm2

Fired bending strength 1300ºC: 53.2 N/mm2

Thermal coefficient 1250ºC (25-500ºC): 60.1x10^-7ºC^-1

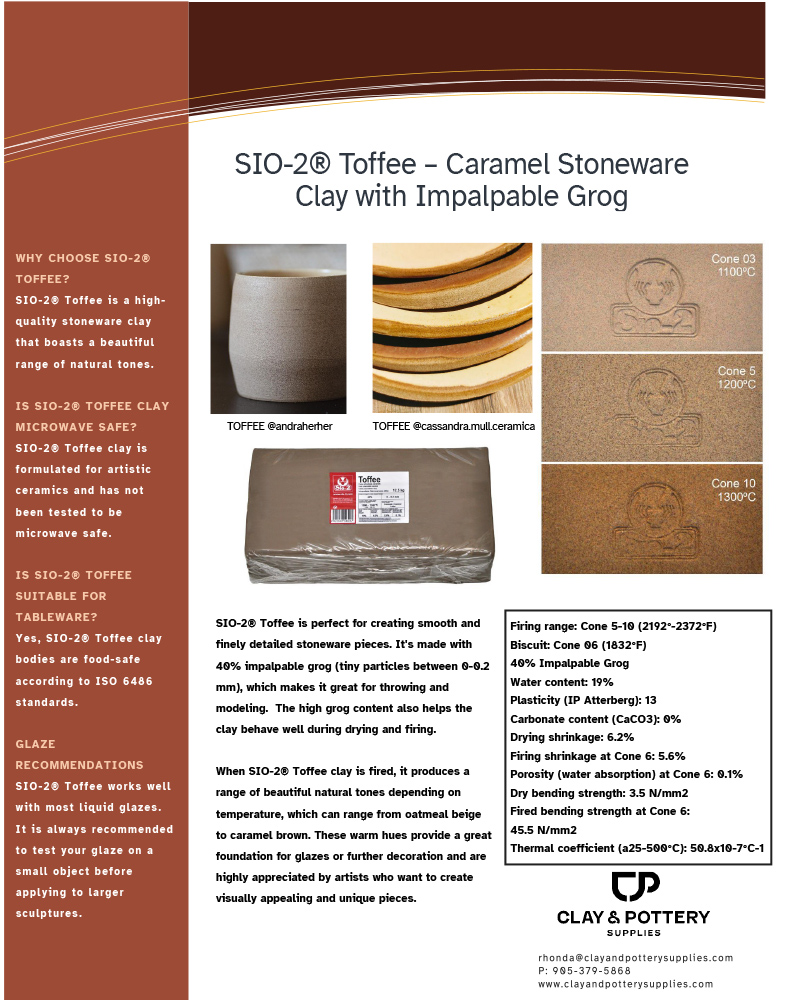

TOFFEE CARAMEL

TECHNICAL SPECIFICATIONS:

Firing range: 2192-2372ºF / Cone 5-10

Biscuit temperature: 1832ºF / Cone 06

Water content: 19%

Plasticity (IP Atterberg): 13

Carbonate content (CaCO3): 0%

Drying shrinkage: 6.2%

Firing shrinkage at Cone 6: 5.6%

Porosity at Cone 6: 0.1%

Dry bending strength: 3.5 N/mm2

Fired bending strength at Cone 6: 50.8 N/mm2

Thermal coefficient (α25-500°C ): 67.6x10^-7ºC^-1

Firing range: 1200-1300ºC / Cone 5-10

Biscuit temperature: 1000ºC / Cone 06

Water content: 19%

Plasticity (IP Atterberg): 13

Carbonate content (CaCO3): 0%

Drying shrinkage: 6.2%

Firing shrinkage 1300ºC: 5.6%

Porosity (water absorption) at 1300ºC: 0.1%

Dry bending strength: 3.5 N/mm2

Fired bending strength 1300ºC: 50.8 N/mm2

Thermal coefficient 1250ºC (25-500ºC): 67.6x10^-7ºC^-1

LUNA SPECKLED

TECHNICAL SPECIFICATIONS:

Firing range: 2192-2320°F / Cone 5-7

Biscuit temperature: 1855°F / Cone 06

Water content: 19%

Plasticity (IP Atterberg): 14

Carbonate content (CaCO3): 0%

Drying shrinkage: 5.8%

Firing shrinkage at Cone 7: 5.3%

Porosity at Cone 7: 0.0%

Dry bending strength: 2.7 N/mm2

Fired bending strength at Cone 7: 29.2 N/mm2

Thermal coefficient (α25-500°C): 61.1x10-7°C-1

Firing range: 1200-1260ºC / Cone 5-7

Biscuit temperature: 1000ºC

Water content: 19%

Plasticity (IP Atterberg): 14

Carbonate content (CaCO3): 0%

Drying shrinkage: 5.8%

Firing shrinkage 1260ºC: 5.3%

Porosity (water absorption) at 1260ºC: 0.0%

Dry bending strength: 2.7 N/mm2

Fired bending strength 1260ºC: 29.2 N/mm2

Thermal coefficient 1250ºC (25-500ºC): 61.1x10^-7ºC^-1

PCLI PAPER

TECHNICAL SPECIFICATIONS:

Firing range: 2052-2320°F / Cone 02-8

Biscuit temperature: 1855°F / Cone 05

Water content: 24%

Plasticity (IP Atterberg): 27

Carbonate content (CaCO3): 0%

Drying shrinkage: 6.7%

Firing shrinkage at Cone 5: 5.8%

Porosity at Cone 5: 5.6%

Dry bending strength: 5.2 N/mm2

Fired bending strength at Cone 5: 39.5 N/mm2

Thermal coefficient (α25-500°C): 55.7x10-7°C-1

Firing range: 1100-1260ºC / Cone 02-8

Biscuit temperature: 1050ºC / Cone 05

Water content: 24%

Plasticity (IP Atterberg): 27

Carbonate content (CaCO3): 0%

Drying shrinkage: 6.7%

Firing shrinkage 1200ºC: 5.8%

Porosity (water absorption) 1200ºC: 5.6%

Dry bending strength: 5.2 N/mm2

Fired bending strength 1200ºC: 39.5 N/mm2

Thermal coefficient 1200ºC (25-500ºC): 55.7x10^-7ºC^-1

Storage: Protect ceramic clay bodies from direct sunlight, avoiding excessive temperature changes and protect from frost.

Use: Technical details are available with information on the characteristics of each product and its use. It is recommended to test clay body prior to large scale use in order to verify suitability in both the ceramic process (shaping, drying, firing and decoration) and the final application that is expected to be obtained.

Safety: All SIO-2® clay bodies are certified by the Art & Creative Materials Institute (ACMI) and conform to ASTM D-4236 safety guidelines.

From the manufacturer of SIO-2®:

CERAMICA COLLET S.A.

Always in your hands

Founded in 1874, our company manufactures ceramic clay bodies for industry, pottery and artistic ceramics, and natural clay for crafts, fine arts and education.

Our target is to innovate, developing products made with natural clay which, in many applications, satisfy the high requirements of our customers. Our Quality System, certified according to ISO 9001:2008, is the setting for continuous improvement. Social responsibility, respect, and care for the Environment are two fundamental points in the philosophy of our firm.

The AP Seal identifies art materials that are safe and certified in a toxicological evaluation by a medical expert to contain no materials in sufficient quantities to be toxic or injurious to humans, including children, or to cause acute or chronic health problems. Children in grade six and lower, and adults who may not be able to read and understand safety labeling should use only non-toxic materials. The AP Seal ensures products are non-toxic when used as intended for young children, the physically or mentally handicapped, and any persons who cannot read or understand the safety labeling on product packages.